Welcome Back!

Home » Blog » What Are Die Cut Boxes – Features and Uses

Last Updated on February 25, 2025 by Steve Harsh

Have you ever seen those boxes shaped like a person or an animal? They’re called die-cut boxes and can be used for various things. You might be wondering what die-cut boxes are and how they’re made. In this post, we’ll answer those questions and more.

Stay tuned!

Table of Contents

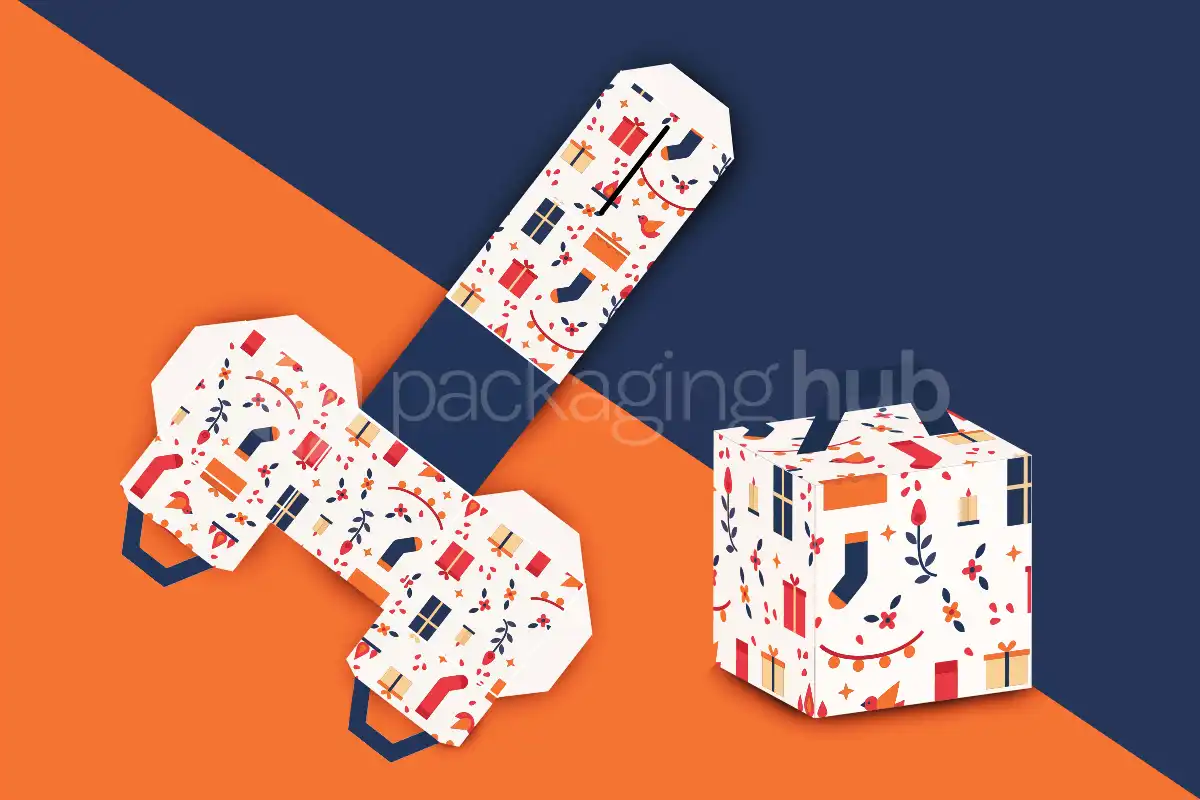

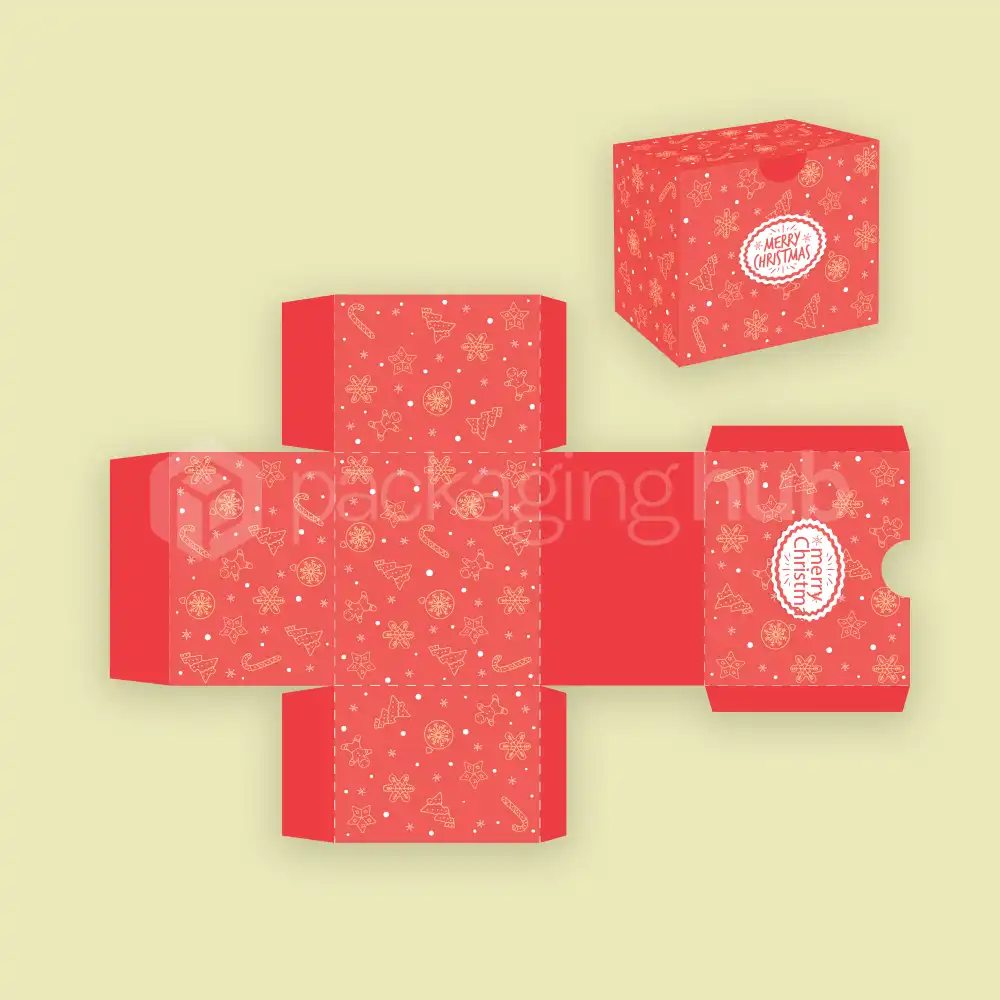

ToggleDie cut boxes are simply cut into a specific shape using a die. A die is a tool with a sharp edge that cut materials like paper and cardboard. Die-cutting is a popular way to create unique packaging for products.

You’ll often find die cutting boxes used for soap, candles, and small electronics. They can be customized to fit the product perfectly and usually have a more premium look than a standard box.

Plus, die cut packaging can be fun and eye-catching. Their unique shapes often make them stand out from the crowd. Die cut cardboard boxes are worth considering if you’re looking for a way to make your product packaging more memorable.

What are Die Cut Boxes Features |

|

| Customizable Shape | You can use die-cut boxes with customizable shapes that offer a wide range. |

| Great Capacity | They have an excellent capacity for any product you would like to use them for. |

| Great Use for Brand Awareness | Using these boxes can help you brand your products well and create awareness around them in numerous ways. |

| Cost-Effective Packaging Solutions | Die cutting box takes less material for production, which makes them a cost-effective product. |

| Easy-to-Use Products | At the same time, they are easy-to-use products you must assemble before use. |

| Durable Construction | They are among the most durable products you can use for your packaging. |

| Versatile Products | These would work for any design you want to use for your products |

| Eco-friendly Boxes | If you want something eco-friendly, you can get these to make your products unique and useful. |

Die cut packaging boxes usually have a few key features that set them apart from other types of packaging. Here are some of the most common:

As we mentioned, one significant benefit of die-cut boxes is that they can be customized to fit your product perfectly. No matter what shape your product is, a die-cut box can likely accommodate it.

Die cutting packaging often has unique and eye-catching designs. This can help your product stand out on store shelves and online.

Die-cut boxes are great for products that require a lot of space. They provide better capacity than packaging boxes and can lower shipping costs.

Using these boxes to build your brand awareness would always be a great choice you can make. Try using these products to build your brand when you use specific colors for branding. These boxes can help you by getting a certain type of advertisement when you add certain colors to them.

Diecut boxes are made from corrugated material, making them a great product because they do not cost too much. This feature makes them a great choice if you want to use them for a unique design. Die-cut boxes often have unique and eye-catching designs, which can help your product stand out on store shelves and online.

At the same time, being unassembled can help you store them easily. So you can use them whenever you need them without having to keep them assembled all the time. Moreover, assembling them whenever you need to use them is easy.

When looking for something cost-effective, you should also look for something that does not require too much material. Using less material can reduce the box’s price, which these boxes are famous for. So, you do not have to spend much on their material, reducing their price heavily.

You can use these products to display products, and there are several goods you can pack in them with ease and facility. You can pack

Die-cut boxes are often made from sturdy materials like cardboard or corrugated paper. This makes them ideal for products needing extra protection during shipping. So, you do not have to worry much about shipping jerks and bumps, as the boxes can take care of that.

You can never go without getting the right design for your packaging. So, you can try using these versatile products to pack several products that you want to look unique. You can also use fantastic shapes and sizes to make a great impression on your customers and clients. Their production uses laser cutting, perfectly cutting precise box sizes like squares, rectangles, or anything else you need.

Eco-friendly is the norm and trend, and no company can deny it. This is why you should always go for green solutions in packaging and printing, which people care so much about. So, using eco-friendly products is something you need to have for your customers.

Eco friendly boxes need to be recyclable, which can completely change how you pack your products.

You might use die cut box for your product packaging for many reasons. Here are just a few:

Creating a die-cut box design can be challenging, but it’s doable with the help of a professional designer. You can also make large quantities of these boxes without spending too much time.

The first step is to develop a general idea of what you want your box to look like. This might involve sketching out a few ideas or looking for inspiration online. Once you have a good idea of your goals, you can start working on the details.

Your designer will need to consider things like the size and shape of your product, the materials you want to use, and your branding elements. They’ll also need to ensure the design can be cut using a die without issues. You’ll likely be allowed to choose from cardboard, corrugated paper, or plastic.

After the initial design, it’s time to start working on the die line. This is a template that will be used to create the actual die that will be used to cut your boxes. The die line must be made using a vector graphic program like Adobe Illustrator.

Once the die line is finished, you must send it to a die maker. They’ll use the die line to create a physical die that can be used to cut your boxes. Die-making can be expensive, so getting quotes from multiple vendors is essential before deciding.

After you’ve received your die, it’s time to start cutting boxes! You must find a printer or packaging company to print die-cut boxes. Once you’ve found a supplier, send them your design and die file, and they’ll take care of the rest.

Die cut packaging design is a great way to make your packaging more memorable and unique. Consider them if you’re looking to stand out from the competition. Remember that the design process can be challenging, so working with a professional designer is important. Good luck!

Order your stylish and durable custom boxes and packaging from a team of industry experts.