Home » Blog » What is Flexography Printing – Facts Need to Know

What is Flexography Printing – Facts Need to Know

Posted April 26, 2023

Printing is a way to make things look great, high-end, and perfect for use. So, what are the common types of printing, and what benefits do they offer? Well, flexographic is among the most common types, with many benefits that allow you to make things more impressive.

So, what do you get when you use Flexographic for your products? What are its benefits, the process, inks, equipment, and when to choose it? Plus, more in this blog.

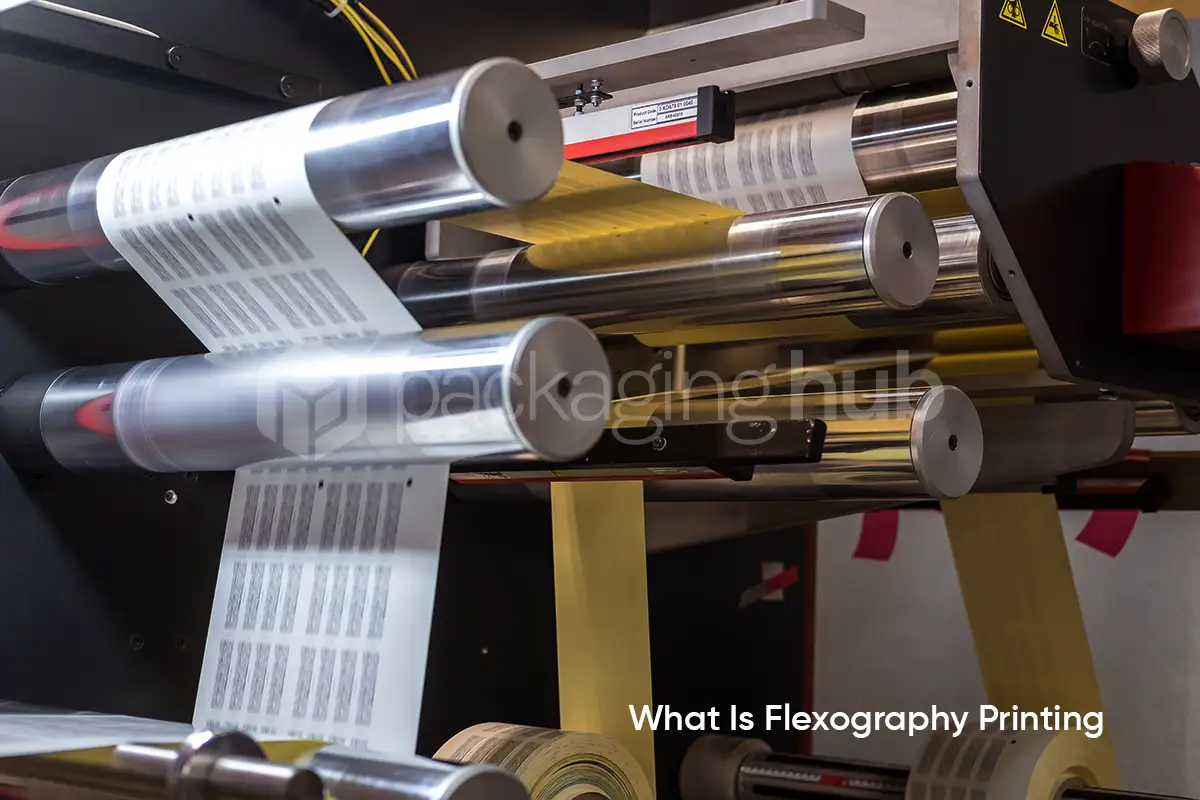

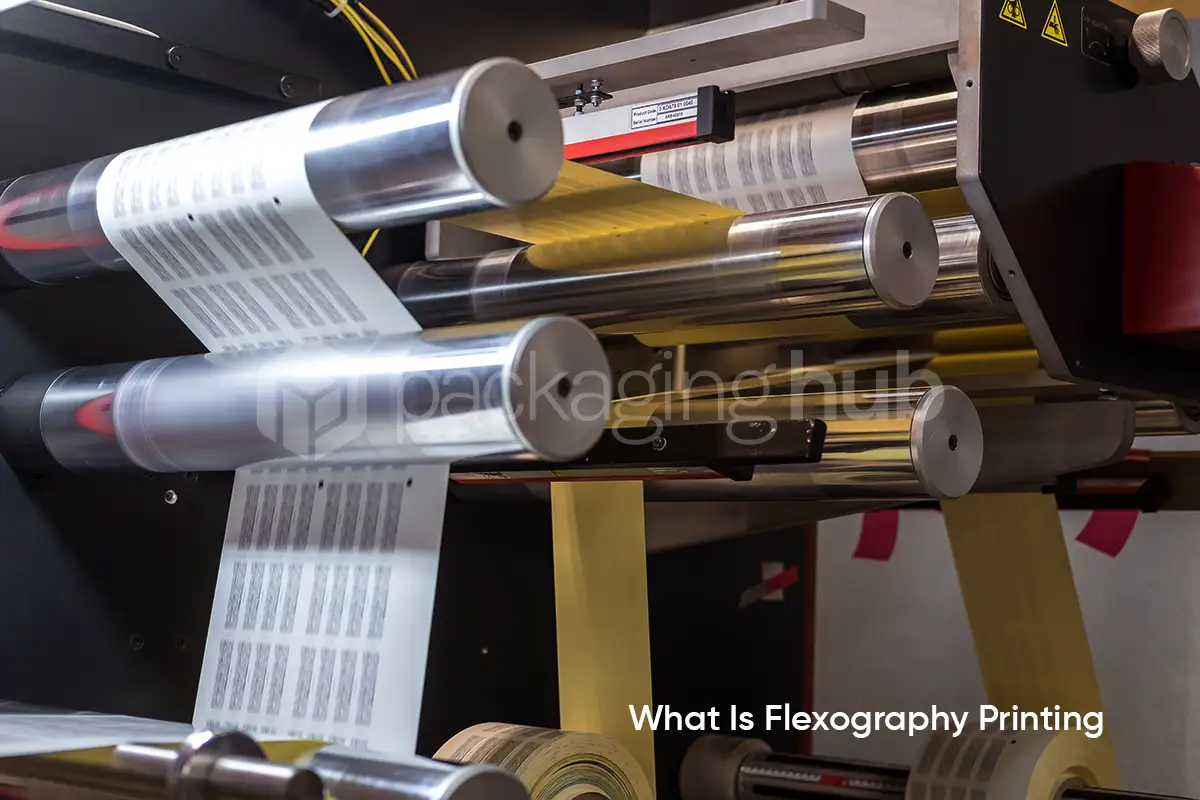

What Is Flexography Printing?

Flexography is a common printing method for high-volume productions, using films, papers, and foils. It uses inks that you can evaporate. One benefit of this type is that you can use it on food products, which allows you to work with various products. In this process, ink is put on the roller, and a blade allows the removal of the extra amount of ink.

This ink comes from the rubber plate, which comes to the letterpress cylinder that holds the ink. Next, the plate that carries the ink allows an image to be transferred to the paper.

Advantages Of Flexography Printing

So, why do we have to do this type of printing? Well, there are multiple reasons, like:

- It is among the types that work for the vastest range of needs. You can try it for many surfaces, including flat, rough, porous, and non-porous.

- Also, you can use it with a wide range of ink. Additionally, it works for a vast range of procedures post-process. At the same time, you can dry it easily, and you do not have to spend a lot of ink on this type.

- At the same time, it offers an eco-friendly solution that makes a huge impact.

- Inline processes make it easier to get prints with this type.

- Another thing to remember is you can get your prints with less money spent owing to less labor, plates, and ink costs.

- Also, you do not have to spend much on bigger print jobs.

- This type also allows you to work with a huge range of colors.

- You can use this one for its ability to create quality content.

These benefits can be a great reason you should be looking to use this type of printing for your jobs.

Disadvantages of Flexographic Printing

Now, knowing the benefits of this printing method can help you decide. The same goes for the disadvantages that you need to know before you go with this type, so here are some:

- It is among the types that do not offer many images.

- This type has complex machinery that can be an issue when working with it.

- The colors you get with flexographic printing can be considered dull sometimes.

- When you use this type of printing, you will have to spend more time preparing.

- At the same time, it would cost you more for smaller jobs, making things good for bigger productions only.

- Flexography can not help you with great results if you change a version of your design.

These disadvantages can be an issue when using this printing type. So, you should be sure you can survive these disadvantages and are willing to get the advantages that matter to you.

Flexography Printing Packaging Pieces Of Equipment

Knowing about flexographic equipment can help you learn many things about this type. So, if you want to use this printing type, you should also understand the basic equipment you should know about.

What is a Print Wheel?

When it comes to this type of printing, you need to know this equipment well. So, you need to know the size of the message you want to print on your product. At the same time, you should figure out the number of times this message will be on your print job. Your wheel’s circumference has a huge impact on the product you get.

The Printer

The printer is an important part of your flexography job and comes in various sizes. You can use them for different material sizes and try using multiple printers simultaneously.

Flexography Printing And Inking Methods

Ink is an important part of your print jobs and can change how things work. Here is what you need to know about these systems:

- The two-roll inking system allows a rubber roller to pick the ink from the reservoir and then take it to the transfer roll. Then, the ink is applied to the plate, which allows you to print on it.

- The single-roll system would use a doctor blade that takes the extra ink from the pickup roller. Also, it ensures the printing plate gets the right amount of ink for your print jobs.

Some Other Pieces of Equipment

There are some other pieces of equipment you need to know about when doing a print job in flexography:

- You should have mounting frames and backup rolls.

- A pneumatic cylinder lets you decide where printers will come on and off.

- Also, you should have motor drives to control the printers well and take them to upline speed.

- Using ink pumps and doctor blade chamber systems will help you get automation in the inking system.

How to Do Flexographic Printing?

In this section, you can read about the process you must follow for flexographic printing. So, here we go:

- The process starts with preparing what will be printed on your product. So, you should make the artwork in software and keep all the specifications you need to consider for the particular job.

- In the second step, the substrate materials are rolled inside the machine, ensuring the process becomes automated without any breaks.

- Then, the substrate roll goes into the printing press. Also, the enclosed chamber inside the press gets ink and fills it. Next, the doctor’s blade chamber determines to remove extra ink.

- The next step is to ensure the ink goes to the image carrier from the inking system. This process becomes possible with an anilox roller with microscopic cells that allow a layer of ink.

- Next, the image carrier allows the image to go to the substrate.

- Your system keeps the best pressure and allows the substrate to get the process between the image carrier and the impression cylinder.

- Then comes the drying process, where roller-less and plate-less dry your ink.

- The last step occurs when your substrate gets rolled up and the die-cutting is done. This way, every piece of separate printing gets separated.

This process gets your flexo printing job done, and you need to learn to master and troubleshoot it to perfect your print jobs.

Types And Features of Flexographic Printing Inks

When it comes to inks, there are some common types you need to know about, like:

- Water-based

- Ultraviolet and electron beam

- Oil-based

- Solvent-based inks

These types have their special characteristics and features.

Features Of Water-Based Inks

Here are some features of water-based ink you need to know.

- Water-based ink comes from pigments and additives that allow them to dry easily and faster.

- They are among the most famous types in corrugated packaging and printing.

- These also would offer higher surface tension compared to other types.

Oil-Based Inks

- This ink type sometimes uses mineral oils, and its solvents are too harsh.

- They are famous for use in the publication section of the printing industry.

Ultraviolet And Electron Beam Inks

- These ink types dry when exposed to UV light or electron beams.

- At the same time, they carry a higher viscosity level, making them different.

- It is among the famous types in the food packaging industry. So, you can use it for wraps that cover the outer part of your food products.

Features of Solvent-Based Inks

- These come with a lower level of surface tension.

- They are considered super special for bags and industrial films.

Flexography Printing Examples

Some of the common examples of flexo printing are:

- Adhesive labels are among the common types of flexo printing.

- Tissue, gift wraps, and wallpapers can also be used.

- You can also use them for folding cartons.

- Shopping bags, plastic bags, and packets come from flexographic printing.

- Also, you can use shrink-sleeve in this sector.

- Ice cream cartons are among the common printing jobs you do with this method.

Packaging Hub Makes Your Jobs Easy!

Packaging Hub has the capacity, ability, and expertise to simplify your job. So, are you looking for a flexo printing job and want to hire a reliable provider? We care for your needs by considering every aspect and making your products look impressive. The better your design, the better you sell, so order now and make your products super-sellable.